Fibreglass Swimming Pools

Fibreglass Pools – Endless Possibilities

In 1999 Trilogy challenged the status quo asking, “Why wouldn’t you be able to have a customized fiberglass pool?” Which led to further questions and the result being:

- made to order fibreglass pools

- large variety of shapes and sizes

- wide selection of colours

- many options to choose from

- accessories to meet your needs

Every Trilogy fibreglass pool is made to order, this means that your pool will not be sitting outside, exposed to the elements and birds, before you purchase it. Your pool will be engineered and built by Trilogy craftsmen to your order specifications. With a Trilogy pool you get perfect combination of swimming pool, surface color, deck, tile, water feature, and water colour.

Advantages of Fibreglass Pools

Fibreglass Pools are Easier to Maintain

Fibreglass pools require less attention. The fibreglass surface is non-porous and inert and thus requires less chemicals to maintain pH and inhibit algae growth. The average fibreglass pool owner only spends about 45 minutes per week maintaining their pool

No Liner Replacement or Acid Washing

Vinyl liners need to be replaced about once every decade, sometimes sooner. Fibreglass is also much stronger and resist tearing from dog claws and long toenails.

Concrete pools need to be acid washed every few years to clean them up and resurfacing approximately every 15 years. This is not necessary with fibreglass pools.

Stands Up To Saltwater

Fibreglass pools have no issues with salt-based chlorine generators that can harm the finishes on concrete pools and, when not properly maintained, cause many components in a vinyl liner pool to prematurely age.

Easy to Install

One great thing about fibreglass pools is that most of the work is done in the factory before your pool arrives on site. A standard installation can typically be completed in a week..

Trilogy Pool Manufacturing

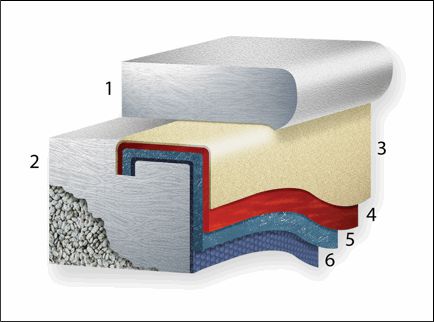

Trilogy uses the highest quality composite resins and gel coats in the industry. Other aspects of Trilogy Pools are:

- Coping Options: Brick, Concrete, or Stone Coping provides an elegant and durable finished edge around your pool.

- Interlocking Bond Beam: The Bond Beam is formed when the concrete deck is poured around and up next to the flange of the pool. This step structurally ties your deck to the outside of the fiberglass pool shell.

- Finishes: HydroStone or Gelcoat, whether you choose one of Trilogy’s 6 beautiful HydroStone finishes or white gelcoat, you are assured of maintenance-free durability for years to come.

- Vinyl Ester Barrier Coat: This layer gives your pool extreme resistance to even the most corrosive chemicals.

- General Purpose Resin: This structural layer of general purpose resin and fiberglass provides the rigidity needed for transportation and installation of your swimming pool.

- Woven Roving + GP Resin: This 24 oz. woven glass cloth is the final laminate for your Trilogy Pool. The glass cloth encases the entire pool in a network of fiberglass. The end result is a swimming pool with outstanding structural integrity.

Layers of Excellence

What to Expect When Having a Fibreglass Pool Installed

Professionalism & Respectfulness

At Creative Pools Ltd. we want to make your experience of having a swimming pool installed as painless as possible. Our commitment to you is that we will be professional at all times, we will show up when we say we will, we will be respectful of your property and family, and we will secure and clean up the job site each day we are there.

Pool Building Process

- To begin with we will sit down with you to determine the size, style and options you want in your pool; including the finishing touches of landscaping, decking, lighting and outdoor audio if desired.

- Measure, take soil samples as required and stake the area.

- Order your pool and accessories and arrange for any other options you have contracted us for.

- Once the pool has been made and delivered we will excavate where the pool will be set in and take the excess dirt away.

Pool Building Process cont’d

- We will remeasure to ensure all the elevations are correct and adjust elevations with gravel.

- Ensure the foundation floor is sound before setting in the pool shell.

- Attach plumbing to the pool shell.

- Lower the pool shell into the prepared hole ensuring the pool is level and seated properly onto the foundation.

- All the main pool drains must be fitted and the plumbing to the pool equipment is completed

- The pool is now filled with water and the shell is backfilled with gravel simultaneously to equalize pressure.

- Pool coping is installed around the pool edges

- Backfilling around the pool is completed

- Accessories are installed

- Any landscaping, decking or other extras can start at this point.